Overview

A medical retirement home had a confirmed case of Legionellosis and needed to make an immediate assessment.

Legionellosis is an illness acquired from Legionella bacteria. The bacteria can grow in multiple places like cooling water, potable water systems, and other locations. The two-building medical retirement home needed to do a quick assessment to target the source and take corrective actions quickly.

They used LuminUltra testing solutions and agreed to share results exclusively in this economic analysis case study.

Introduction

A case of legionellosis – an illness caused by Legionella bacteria that can cause pneumonic (Legionnaires’ disease) and non-pneumonic (Pontiac disease) forms of infection – was diagnosed in a medical retirement home. An investigation was conducted to identify potential sources of the outbreak and immediately implement corrective measures. Samples were collected from various locations in the potable and hot water systems, and then analyzed for the presence of Legionella bacteria using culture testing.

Culture tests vs. ATP testing

Unfortunately, Legionella culture tests require up to a week to complete. Because of the health risks associated with Legionella bacteria, more rapid testing was also performed to quickly assess the biological growth throughout the water system and identify locations that were at a higher risk of harbouring the bacteria.

This testing was completed by measuring adenosine triphosphate (ATP) using LuminUltra’s 2nd Generation ATP test kits. ATP is considered the primary energy carrier for all life, so ATP concentrations can be used to provide a direct measurement of total microbial content. The advantage of using ATP testing in this application is that it can be completed within minutes, rather than days, as required for the various culture test methods.

Methodology

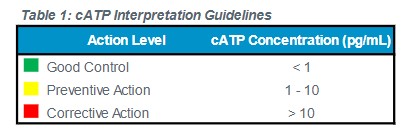

ATP testing was completed using LuminUltra’s QGA test kit. This method was developed specifically for measuring a wide range of ATP concentrations in filterable water samples. The kit measures cellular ATP (cATP), which is contained only within living cells.

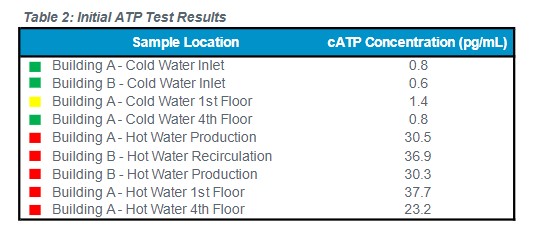

The results of the initial monitoring are shown in Table 2. The colour codes have been included to illustrate how the measured concentrations compare to the action levels provided in the interpretation guidelines.

Increased levels of microbial activity in hot water systems are common. This is because higher temperatures rapidly degrade disinfectant residuals and promote biological growth. Furthermore, water use patterns in hot water systems typically include longer and more frequent periods of stagnation, which promote biofilm formation and lead to increased hydraulic residence times. Because of these factors, hot water systems are at an elevated risk of harbouring pathogenic Legionella bacteria, which thrive within biofilms and favour warm temperatures in the range of 20°Cto45°C .Therefore, controlling biological growth in hot water systems is critical for preventing the growth of Legionella bacteria.

Taking corrective action

Corrective actions were implemented at all sites with cATP concentrations greater than 10 pg/mL. Corrective actions included increasing the temperature in the hot water system to a level that inhibits Legionella growth (55°C was used in this application)and by performing intensive flushing on a daily basis until cATP levels reached appropriate levels.

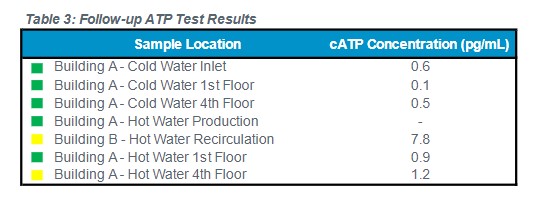

After increasing the water temperature in the hot water system and conducting an intensive flushing program, cATP concentrations decreased to levels that were below corrective action concentrations. At two locations, cATP concentrations remained slightly elevated after the initial flush, so continued monitoring and flushing were recommended to further reduce risks associated with Legionella.

Economic analysis

The most significant advantage of using ATP testing is that the results are available within minutes, so monitoring, corrective actions, and follow-up testing can all be completed within a 24 hour period. If ATP testing was not available, then operators would have likely relied on heterotrophic plate counts (HPCs) as an alternative microbiological monitoring method.

The major difference between these two procedures is that plate tests require up to two days of incubation time. This would have meant that corrective actions would have been required at all sample sites until results were available, and then flushing could have been reduced to only the sites where biological growth was high until follow-up test results could confirm that the corrective actions were successful.

Additional labour would have been required to conduct the extra flushing if HPCs were used rather than LuminUltra’s 2nd Generation ATP testing. The costs for HPC tests are also approximately three times higher than the cost per QGA test. In total, labour and testing costs1 would have been approximately $450 higher if monitoring was completed using HPCs. Moreover, significantly more water would have been wasted through excess flushing while waiting for the HPC results.

While the financial savings are relatively minor, the key benefit was achieved through protecting public health.

Benefits of ATP testing

ATP testing was able to help operators meet their principal objective:

- prevent further infections by immediately identifying high-risk areas

- implementing corrective actions, and

- verifying that those actions were successful.

Legionnaires’ disease is a serious illness that in some cases can be fatal. Hospitalization and intensive treatment are often required, and researchers have estimated that average treatment costs are $40,000 (£30,0002, 3) per incident of the disease.

1 Based on $30/hour salary and benefits, 15 minutes per location to complete flushing, and $30 per HPC test.

2 Lock, K.; Millett, C.; Heathcock, R.; Joseph, C.A.; Harrison, T.G.; Lee, J.V.; Rao, G.; Surman-Lee, S., 2008; For Debate –Public Health and Economic Costs of Investigating a Suspected Outbreak of Legionnaires’ Disease. Epidemio. Infect., 136:1306.

3 Original cost was cited in GBP. The USD figure shown was calculated using conversion of $1.33 USD to £1 GBP