Updated January 2021

You may have heard of quantitative Polymerase Chain Reaction (qPCR) in the news recently as the gold-standard testing method for COVID-19. But did you know that this technology can be used to test for harmful organisms in industrial processes?

Identifying the presence of invasive and potentially damaging organisms in industrial processes can save organizations from costly problems like product degradation, infrastructure corrosion, and process inhibition. The sensitive, objective, rapid, and specific results provided by qPCR testing gives system operators a powerful new tool to assess and manage risk.

What is qPCR?

Quantitative Polymerase Chain Reaction (qPCR) is a DNA-based testing method that rapidly detects and quantifies microorganisms in environmental or industrial samples.

Different qPCR assays are used to identify concentrations of key groups, such as total prokaryotes, sulfate-reducing prokaryotes, or iron-reducing bacteria.

qPCR can be used to:

- Understand the cause-and-effect relationship that different microbes have on processes

- See trends and understand future triggers for proactive vs. reactive decision-making

- Apply more targeted, effective, and cost-efficient treatments

How does qPCR work?

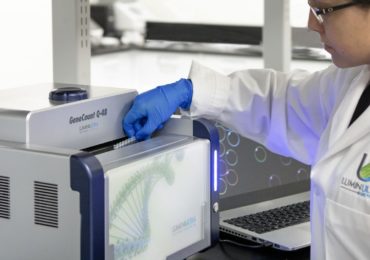

qPCR testing involves cycles of heating and cooling that serve to replicate a specific DNA sequence (gene) from a target organism or organisms. As the target DNA sequence is replicated, the amount of a fluorescent tag increases proportionally to the replication of the target DNA sequence. This fluorescence is directly measured in real-time by the qPCR instrument.

The raw data result obtained from a test is known as cycle threshold (Ct). It indicates at what point in the reaction the fluorescence of the target increased above the level of the baseline fluorescence. Combined with a standard curve created using known concentrations of the target DNA sequence, it is possible to calculate the amount of gene copies present in the original sample, whwhich can be expressed as a concentration of gene copies/mL (or gene copies per gram or surface area).

With this data, operators can better understand which microbes are having the most impact – good or bad – on their system.

How does qPCR differ from traditional testing methods?

Culture tests via plate counts and bug bottles have been popular testing methods. Trusted by technicians and managers for their high degree of specificity. However, qPCR provides a number of advantages:

- Fast: Delivers results in under 2 hours from sample collection

- Flexible: Allows for analysis of multiple samples and assays in a single run

- Specific: Screen for specific microbes, or groups of microbes significant to your process

Historically, qPCR testing could be relatively complex compared to culture-based tests, but LuminUltra’s GeneCount® qPCR provides a complete off-the-shelf solution with assay kits designed and optimized for identifying key target organisms in contaminated samples from industrial, oil & gas, and wastewater facilities.