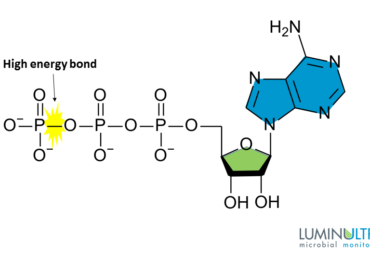

You’ve likely heard of ATP technology, but may not have had the time to fully explore the value it can bring to your existing microbial monitoring program. Here’s a brief overview on how you can use ATP testing to identify and mitigate microbiological issues in your drinking water treatment and distribution system.

Traditional testing methods

If your microbial monitoring toolbox consists of plate counts, like HPCs, and more specific biological tests like Colilert and BART analyses, you’re likely waiting at least 1-2 days for results and missing a large portion of the overall microbial population that’s present in your system. While there is value in the data obtained from these methods, they are not well-suited to assess total microbiological risk or to quickly troubleshoot issues that present themselves.

These limitations are causing more and more water utilities to implement ATP testing because of its ability to quantify the total biological population in less than 5 minutes.

How to incorporate ATP testing into your microbial monitoring program

Here’s a quick guide on how – and where – to incorporate ATP testing into your microbial monitoring program/process:

Distribution system troubleshooting

When utilities experience water quality issues in their distribution system it doesn’t take long for consumers to notice. During periods of increased water quality complaints, ATP testing can immediately be taken into the field to determine whether there is increased microbial growth in the distribution system, identify premise plumbing issues, or to confirm that it’s a non-biological issue. If microbial contamination is detected, ATP allows operators to quickly trace the lines to identify the root cause while still in the field.

Learn how distribution system operators borrowed ATP testing from their treatment plant to identify and repair an un-listed valve in their distribution system that was causing poor water quality and, as a result, reduced water quality complaints.

Confirm water quality after line breaks and repairs

After line breaks, repairs, flushing and troubleshooting activities, distribution operators are typically required to confirm microbial water quality and, in some cases, submit samples for compliance testing. The turn-around time is typically 24 to 48 hours, requiring operators to leave the site and wait for the results. ATP testing allows operators to confirm microbial water quality on-site and ensure that corrective actions were successful to reduce the risk of failed compliance tests.

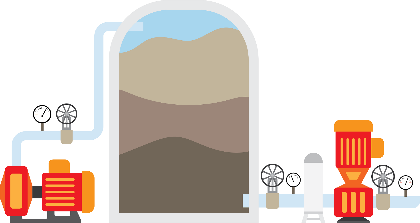

Identifying fouling in membrane filtration units

One of the major challenges of managing a membrane filtration plant is preventing and treating fouling which reduces treatment efficiency and increases operational costs. By monitoring ATP levels in the influent and permeate, biological fouling can quickly be identified, helping operators determine the appropriate treatment type and cleaning schedule, and highlighting design inefficiencies that increase the fouling rate.

Monitoring biofilters

Monitoring the active microbial population in biologically-active filters through ATP testing directly on the media can help operators who are converting conventional filters, managing optimization trials, or troubleshooting treatment issues.

Find out how one researcher developed a TOC removal model using ATP concentration and EBCT.

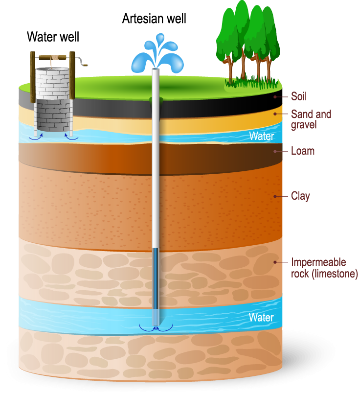

Source water monitoring

Many utilities experience varied and changing source water quality. ATP testing can help identify changes in the microbiological population that can affect downstream treatment processes. From potential algae growth to contaminated groundwater wells, ATP can help water treatment operators quickly identify and remediate areas of high risk.

Learn how this water treatment plant quickly identified and remediated a contaminated groundwater well that was causing issues in their treatment process and showing no growth with traditional HPCs.